Motor sailingboat Roberts 53 mod. (57) - Multi bent frame steel version

as unfinished self-construction (certified by an assessor)

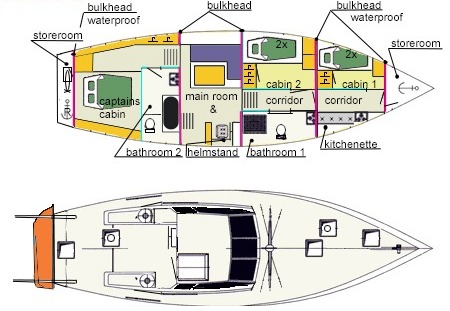

Here is the floor plan and a short 7 minute-video that can best give you a current impression of the interior of the boat. The details of the boat follow afterwards.

|

Overview jump marks to click: Technical details of the hull Technical details of the interior What else needs to be done? Existing parts that can still be installed |

If you are interested in organizing or assembling the rest of the boat project yourself, please contact me

(click here) or via this address:

[ Bruce-Roberts58@gmx.de ]. A viewing appointment can be arranged on site. The sale is in accordance with German law and notarized. I look forward to your requests. Best regards, Matthias Teschner |

Details of the plan view

|

|

Technical details of the hull: Back to overview

- The hull material is structural steel according to EN 10025-S235 JR with the following dimensions:

- Frames 10x70 mm

- Deck and side panelling has a material thickness of 4 mm

- The keel-sided panelling has a material thickness of 6 mm

- The keel bottom has a material thickness of 12 mm

- The skeg is double-walled due to the stability and has a material thickness of 4 mm for each layer

- Inside and outside, the steel hull was blasted and primed.

- The exterior was pre-rolled with International Industrial primer and paint. In addition, three layer coats of airless were subsequently applied with the following components: Primer Intergard 263, Intershield 300 bronze & aluminum base, as well as above-water preserved with Interthane 300 varnish.

- The color in the above water area is RAL 5022 marine blue, red RAL 3002 and on deck white RAL 9002 + sanded anti-slip surfaces in RAL 7032. (For details see: RAL colour standard

- The safety windows are firmly glued.

- The entire inner surface was foamed with a rigid foam layer (PU) 5-8cm for thermal insulation and then covered with plywood and white plastic in the area above the waterline in the living area.

Technical details and details of the interior: Back to overview

- All rooms except for the storage rooms in the bow and stern areas are equipped with a hot water radiator (radiator), which is powered by a fully installed oil central heating (and diesel). This heater is also responsible for the hot water supply and also has a 100L hot water tank.

- The built-in marinized 6-cylinder Perkins diesel engine was completely disassembled and overhauled before installation.

- The reversing gear and the shaft system made of stainless steel are completely new. Both components are completely installed except for the gas transmission cable. Gas lifts and trains are available but still need to be installed.

- The likewise existing rigid propeller and the bow thruster are made of bronze and still have to be mounted.

- The bollards, the cleats, the stanchions, the Davids, the rigging rails for the rig, handrails and the pulpit are made of stainless steel.

- here is a 24V electrical system for general consumers (lighting) with voltage transformer and 220V connection available.

- In addition, various tanks for service water, fresh water and fuel were installed.

- The rudder gearbox is hydraulically installed with two pumps (inside and outside steering position) and also has a SIMRAD autopilot.

- A depth sounder is also available.

- The built-in windlass is designed for a 14 mm wire rope and has been assembled from a German army tank winds themselves. If necessary, this can be removed and replaced by a conventional windlass.

What else needs to be done? Back to overview

- The electrical system has been installed but must be checked, inspected and documented.

- It is recommended to inspect and document the pipes and hoses as well as the connected valves and their pumps.

- Gas control levers for engine and transmission still need to be installed. (the corresponding parts are available)

- The bow thruster still has to be coupled with a hydraulic motor, and a safety cover made of stainless steel still has to be built.

- The kitchen should still be realized according to your own ideas. (Not included)

- The external helmstand still has to be built. (Partially present [engine instruments, steering wheel and throttle])

- Davids and dinghy still need to be mounted. (Parts are completely present)

- The engine batteries still need to be installed. (are not included)

- Optical work such as cleaning the inside surface, screwing on decorative caps, repairing minor damage to paintwork must be carried out, upholstery and carpets can be changed according to taste.

- Small parts such as door locks, slatted frames, switches etc. must be installed later (parts are available)

- On the underwater area, primer and antifouling should be applied before watering. (Separate paint not included)

Parts that are available but not yet installed: Back to overview

- Different fans,

- ship's bell

- 2 stainless steel steering wheels for inside and outside helmstand

- 1 leather seat of the captain (black)

- For the available stainless steel Davids: 2 electric winches 24V + 2 winches manual operation

- echo sounder

- SIMRAD controller

- Modified dinghy (orange) PE material + outboard motor and dinghy support (+ 2 rudders)

- Double propeller bow thruster

- in total 4 anchors = 1 main anchor + 2 replacement anchors (+ 1 additional additional anchor if required)

- 14mm x 100Meter electroplated Steel cable for the windlass

- Electrically foghorn

- Various lamps, position lights ...

- Rest two-component paint from "International". (Red, white, gray, primer, thinner ... see description above)

- If required, a complete stationary solar system (4 solar cells) with 2 AGM gel batteries, additional voltage transformer and solar charger. The facility is designed for small holiday homes and designed accordingly (similar to this version)

If you have further questions, you can contact me via the following email: (click here) or via this address: [Bruce-Roberts58@gmx.de]

Best regards,

Matthias Teschner